Watts Water Technologies transforms its digital prototyping data into Building Information Modelling (BIM) content for AEC customers.

Since 1874, the Watts Water Technologies family of leading brands including Ames Fire & Waterworks, Blücher, Brae, Dormont, Febco, Mueller, Orion, Powers, Sea Tech, Watts Radiant, and Watts have designed and manufactured valves and related products that conserve and control water used in commercial, residential, industrial and municipal applications.

A longtime Autodesk customer, Watts Water Technologies relies on Autodesk Inventor to digitally prototype new products.

Now, the company is using its digital prototyping data to create BIM content and to make it readily available to its architecture, engineering, and construction (AEC) customers. Using Autodesk software, Watts Water Technologies has been able to develop BIM content faster, repurpose manufacturing content for marketing materials, and capture market share by meeting customer demands.

The challenge

Watts Water Technologies is committed to innovation. Past innovations have included converting to lead-free materials and designing a new type of thermostatic mixing valve.

The company also strives to deliver exceptional customer service. So when it began to hear rumblings about BIM, it listened. “Increasingly over the last five years, mechanical, engineering, and plumbing (MEP) engineers have started requesting 3D and 2D CAD data to use in their designs,” says Steve Hofmann, marketing CAD designer and illustrator at Watts Water Technologies. “We realised that we needed to look into how to leverage our manufacturing data to produce the BIM content

they wanted.”

The solution

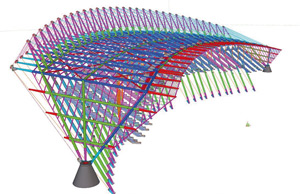

Watts Water Technologies relies on an all-Autodesk workflow to produce its manufacturing data. The company develops new product designs using Autodesk Inventor, which helps speed the process of creating families of parts.

Autodesk software is also instrumental in helping Watts Water Technologies reduce the amount of high-cost materials in its parts, while maintaining structural integrity and agency-approved flow rates so parts do not have to be recertified.

To that end, Watts Water Technologies tests and analyses the digital prototypes it creates in Inventor using the software’s built-in simulation and analysis tools. Once it has validated product performance digitally, the company sends Inventor files to its shop, where they are used for manufacturing. “Using Autodesk software has definitely cut back on the number of physical prototypes we have to produce,” says Mr Hofmann.

From digital prototyping to BIM

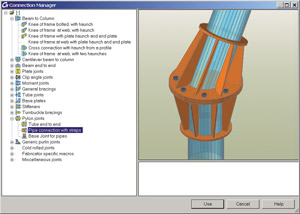

Watts Water Technologies uses AEC Exchange functionality in Autodesk Inventor software to efficiently turn the same Autodesk Inventor data used for manufacturing into the BIM content requested by its AEC customers.

Creating and publishing this BIM content now takes a fraction of the time it once took. Mr Hofmann uses existing Inventor files and AEC Exchange functionality within Inventor to simplify and export them to Autodesk Revit-based software.

He then adds additional metadata that MEP engineers may want — such as weights, ordering codes, flow rates, and hyperlinks to specification sheets and installation instructions.

“With AEC Exchange, we are producing BIM content for entire product lines in three to four hours,” Mr Hofmann says. “In cases where we have already created a template, we can turn the manufacturing data for a product line into BIM content that our customers can use in less than an hour.”

Autodesk Seek

Watts Water Technologies publishes its BIM content to Autodesk Seek, a web service that connects architects and engineers with manufacturers. “Right from a Revit-based product, our customers can search for parts and insert them into their designs,” says Mr Hofmann. “Then they can do analysis on flow rates or generate an accurate list of building materials for the construction manager.”

Extending manufacturing data

Watts Water Technologies is finding other uses for its manufacturing data. With Autodesk Showcase software, the company has begun to develop realistic renderings of products it can use in marketing materials. “Everyone is wowed by the images,” says Mr Hofmann.

Watts Water Technologies is also in the midst of implementing Autodesk Vault Professional data management software. With help from Vault, Watts Water Technologies plans to mine its Autodesk Inventor data to better understand how much material it needs to purchase for manufacturing. As a result, Watts Water Technologies will be able to project material costs as commodity prices change.

The result

With Autodesk software in its corner, Watts Water Technologies not only designs its products efficiently, but makes its manufacturing data readily available to sales, marketing and finance teams who can use it to generate more sales and lower costs.

“We have heard nothing but good feedback. Many of our customers have told us that they will use us over anyone else because we give them 3D BIM content. Autodesk products are definitely helping us gain market share,” says Mr Hofmann.