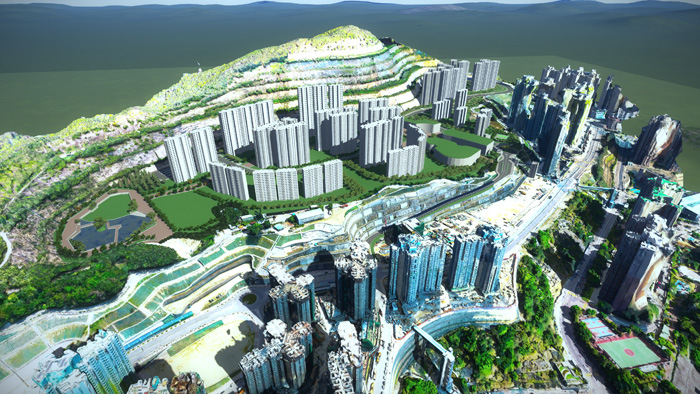

AECOM used reality modelling to help transform the dangerous terrain of a Hong Kong quarry into a commercial and residential development for 25,000 people

To support the surge in economic development and population, Hong Kong has invested in numerous large-scale infrastructure works and new building structures.

For more than 50 years, Anderson Road Quarry supplied aggregate, asphalt, stone, and concrete for construction programs in Hong Kong. Now a vacated site, Hong Kong’s Civil Engineering and Development Department (CEDD) has initiated a USD 1 billion project to develop the quarry in response to the acute housing shortage, the result of rapid population growth.

The quarry site offers 40 hectares of land to construct approximately 9,400 private and subsidised housing flats to accommodate a planned population of 25,000 people.

AECOM was retained as the engineering consultant for sustainable infrastructure design, including site formation, road improvement works, pedestrian connectivity facilities, underground utilities, and housing estates. The company turned to BIM and reality modelling technology from Bentley Systems to optimise planning and construction efficiency, streamline workflows, facilitate stakeholder communication, and meet client reporting requirements.

Safe and accurate site monitoring

As part of the project, AECOM was required to report to the client about the construction progress on a monthly basis. Traditional survey methods for the 40-hectare quarry site would have been inaccurate and inefficient because the quarry’s terrain was steep, sloping, and immense. Additionally, using manual photography to monitor progress would put surveyors at risk, capture only a portion of the area, and take 40 days to complete, missing the required 30-day reporting deadline.

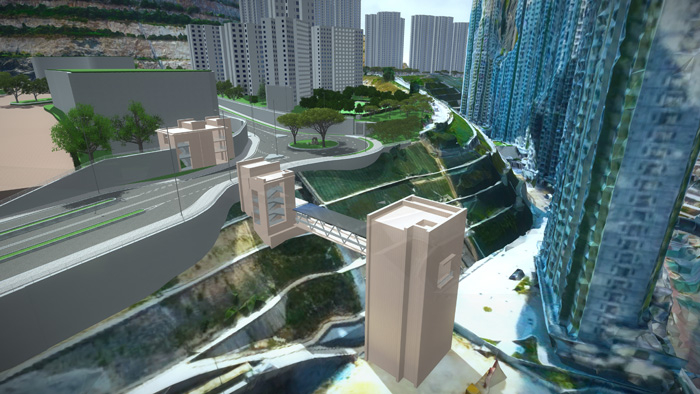

To overcome the challenges of the site’s topography within the client’s 30-day reporting timeframe, AECOM decided to use reality modelling to best monitor the site’s progress. Using drone photogrammetry, the team captured 3,000 photos monthly and used ContextCapture to generate a reality mesh of the entire site for an accurate visualisation of the construction progress within one day. The 3D precise and real-textured reality mesh provided the team with an efficient and comprehensive platform to oversee site progress and eliminated the need to have on-site staff perform the survey, avoiding potential hazards and improving safety.

Reality modelling meets 4D

Beyond creating visualisations, AECOM understood that reality modelling provides a comprehensive record of a site’s current conditions that can be utilised in the future. Leveraging Bentley BIM methodology and reality modelling capabilities, AECOM partnered with Earth Solutions to implement a Site Data Management Solution (SDMS), using ContextCapture as the foundation.

This innovative construction management solution extended the function of reality meshes from visualisations to more informative uses to achieve a full 4D BIM methodology approach. The ability to add information, such as key construction dates, images, and BIM renderings, to specific points in the reality meshes optimised planning and construction.

By automatically overlaying models, the SDMS highlights locations or changes in height to visualise works in progress and cut and fill volumes for easy interface of earthworks balance, all in the same platform.

The use of reality modelling for topographic surveys and photo recordings saved a total of 55 resource-days per month and using the SDMS for automating and processing data saved over 200 resource-days.

The combined solution streamlined workflows and improved communication among the team and with stakeholders, minimising rework and significantly reducing project costs.

Construction management

With different disciplines required for the site and infrastructure development, it was necessary to have accurate collaboration and information sharing among the team and with stakeholders.

The mass quantity of project data was managed and analysed in ProjectWise; that information was attached to reality meshes in SDMS and on-site building contractors and team members accessed the data through their mobile devices. This set-up enabled any conflicts regarding site boundary and foundation works to be identified and resolved prior to construction for more careful planning.

The enhanced information mobility enabled fast, temporary traffic diversion arrangements and minimised impact to travelling citizens. Integrating LumenRT to simulate construction progress and produce animated visualisations helped communicate progress to the public adjacent to the site.

Having an effective, integrated construction management solution optimised collaboration among AECOM, the contractor, the client, and the public for a holistic project approach.

The technology enabled AECOM to work closer with the contractors for more efficient supervision and allowed the building contractors to anticipate and solve problems in advance.

The use of reality meshes provided more precise and accurate site monitoring through detailed visualisations, enhancing client decision making and facilitating citizen understanding of the construction progress.

“By creating synergy between our expertise in project management and the further utilisation of reality modelling and BIM, we successfully increased productivity and safety,” said Ivan H.K. Tsang, vice president at AECOM Asia.

Future smart city

Anderson Road Quarry will serve as the fundamental model to develop other communities in Hong Kong that, when combined, will gradually form the smart cityof Hong Kong.

Although the model was populated with facility data for this specific project, it can be integrated with other data sources for uses in other cases, ranging from energy efficiency and environmental sustainability analyses to generating master plans for future facility, transportation, utilities, and security plans.

If you enjoyed this article, subscribe to AEC Magazine for FREE