Nemetschek’s Vectorworks has delivered its yearly update to its flagship BIM modelling suite of products and the news is, it’s a big one, offering some unique capabilities. Martyn Day evaluates

Munich-based Nemetschek is a very unusual software company. All of the other software developers in the industry have one BIM product. Nemetschek owns three: AllPlan, ArchiCAD and Vectorworks.

With sales in over 85 countries and a very strong presence in Europe, the company seems comfortable with selling what, on the face of it, appear to be competing platforms.

Allplan and ArchiCAD have their origins in Europe. Vectorworks was born in the mid 1980s and started off life as MiniCad for the Apple Macintosh. Around the year 2000, it transitioned to the Vectorworks brand when it was acquired by Nemetschek. Each of Nemetschek’s BIM brands are run as separate concerns and have different approaches, methodologies and underlying technologies to deliver on the process of BIM.

Despite its apparent age, Vectorworks has been undergoing a radical re-architecting and a fleshing out of its BIM capabilities. Until recently, it was only one of two platforms for construction that used a solid modelling kernel to underpin its geometry. Both Bentley Systems and Vectorworks utilise the Parasolid kernel from Siemens. There’s also a new kid on the block called BricsCAD, which uses the ACIS kernel. It turns out that having a powerful geometry engine, usually found in manufacturing CAD systems, may well be a better match as the industry moves to embrace digital fabrication.

In this release, Vectorworks has actively exposed some of the more powerful solid modelling methodologies of Parasolid, to make accurate manufacturable components, but more on that later.

One other unique feature in the Vectorworks offering is the way that the technology comes in a variety of flavours. There are seven options to choose from. Landmark is a very well-regarded and comprehensive landscaping variant and Spotlight has single-handedly developed a leading role in the world of stage and lighting design. The others are Fundamentals, Architect, Braceworks, Vision and Designer.

The feature updates range across these variants, some being common, some being unique to the industries that are focused upon.

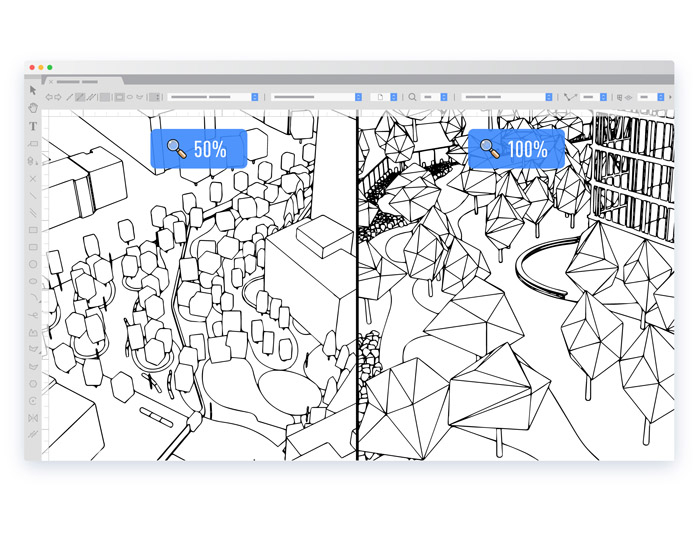

Graphics

The first thing you notice with Vectorworks 2020 is the smoothness and speed of the new graphics, especially on large files. Using games style, dynamic Level of Detail (LoD) control, objects far away or not in view are reduced in detail on the fly, optimising the load on the graphics card. This is used when zooming, panning and using ‘fly over’ in the model. Files open faster and 3D frame rates are improved.

Live data visualisation

This new feature enables components within the building to be assigned colour attributes, depending on their object parameters. It could be used to check models visually during the design process.

Live data visualisation is like a lightweight Solibri capability, so you could instantly see which doors lacked fire protection or what are supporting structures vs partition walls. It could also be used for massing analyses with various residential units, or in the Landscape variant, to see which plants had the highest solar requirements, pricing or water needs.

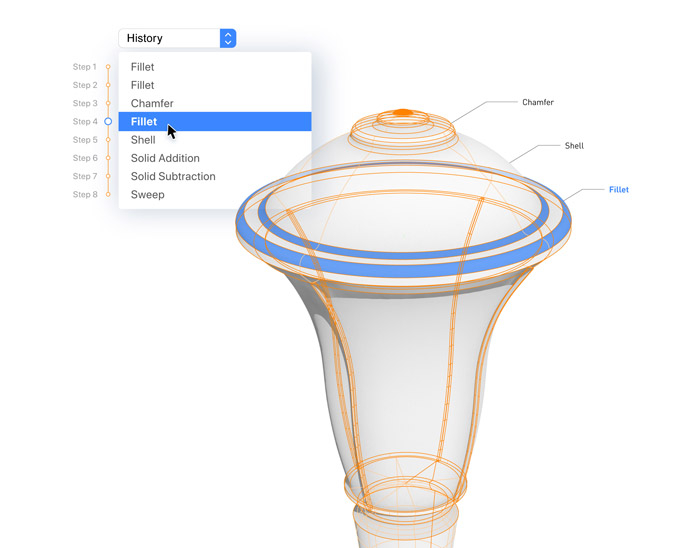

It’s completely user configurable and it’s possible to have colours automatically associated to groups of components, such as fire door rating times, for instant identification within your model. Multiple visualisation sets can be created through a simple interface and stored/reapplied throughout the design process. These can also be shared between files and projects. History-based modelling This is a feature I never expected to see in an architectural design tool.

History-based modelling is a common modelling paradigm in manufacturing CAD. Essentially, to achieve the desired geometry, a range of operations are applied to define the shape of the building component, such as rounded edges, fillets, shells and chamfers. The history tree is the recipe of sequential commands used to create the component and they can be edited or removed from the tree, impacting the resultant component when ‘rebuilt’.

There are navigation tools to run through the history and locate the function that needs changing, and after all edits made the software re-builds the component to reflect the changes. This approach to modelling allows for an iterative design process and means components don’t necessarily have to be deleted and modelled from scratch; old designs can morph into new variations.

The addition of history-based modelling is a great capability, exposing the Parasolid core to create components or structures which might get digitally manufactured.

Revit export

I’m sure that many Vectorworks customers have requested Revit export. In fact, I’m sure many customers of every BIM tool have requested this capability, but not many software firms are willing to do it. Part of this reason could be to ignore the gorilla in the jungle but there are technical issues, which arise from attempting to support another company’s proprietary format, as it opens all sorts of questions as to data coherence, mapping of components and a commitment to constantly chase file formats when they change.

Vectorworks is a strong supporter of Open BIM, and the company states that IFC is the preferred format, but there are times when collaboration in a native format is required, or when a deliverable needs to be in a specified form. Using technology from the Open Design Alliance (ODA) BIM library, the software can export RVT and RFA files. However, expectations must be set. This is by no means a 100% conversion of BIM to BIM. In this release, only 3D geometry will be exported for Revit to load as generic geometry.

For an initial release, this is a good start. I am sure as the ODA libraries improve, model information beyond geometry will start to be included.

Walk through animations

Once you have completed your beautiful model, nothing beats the generation of a walk-through animation and in this release the development team have reimagined the previous capabilities. Users can create a custom path for the eye-level camera view to travel with a NURBS curve or polyline. It’ll automatically take into account stairs and avoid model surfaces.

You can adjust the camera focus and speed through key frames in the multiple viewports, or from running through the actual camera path. There are two new commands to help assist in the automatic generation of smooth paths. ‘Create orbit’ and ‘Create spin’ will automatically generate paths around selected objects.

These can be exported as movies and rendered with various styles. It’s even possible to render a path and allow realtime 360° user-controlled camera views, as it plays. If you’re a select service member you can use the Vectorworks cloud to render your animation, at various sizes and frames per second.

GIS integration

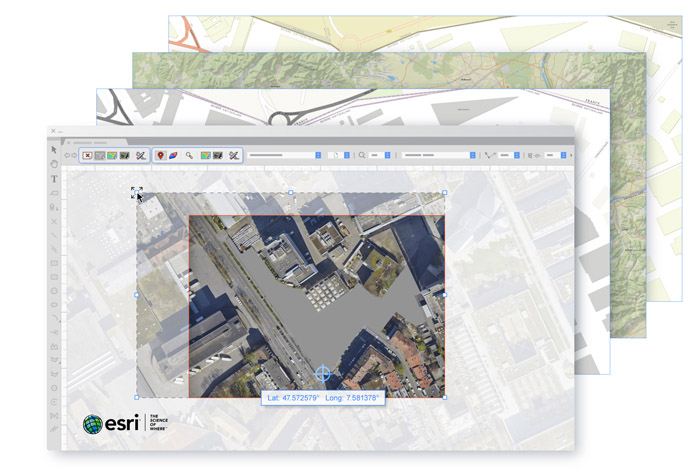

Vectorworks 2020 features a whole new updated Geographic Information System (GIS) toolset which has an integration with the online services of market leader, Esri. Connecting ArcGIS and BIM enables project models to be positioned highly accurately and a digital geographic model created.

Projects can be accurately geolocated simply by entering an address and instantly incorporating street map, satellite, or other imagery in your design through ArcGIS and WMS servers. With a paid ArcGIS online service plan, it is possible to access additional maps and other imagery directly from within Vectorworks.

The development team has replaced the previous Global projection system with a much more accurate Pseudo- Mercator projection.

This link with Esri is quite a coup for Vectorworks, as it manages to deliver a powerful Esri link in its BIM product before even Autodesk managed to, and that was announced almost two years ago.

Data manager

The great thing about BIM is that it’s where geometry and building information combine. The bad thing about BIM, is that there is a whole lot of data and it just keeps growing through a project’s development. To help out, the development team has implemented a new Data Manager to help sort and find needles in a BIM haystack and develop company BIM standards.

It’s possible to gather, filter and organise select objects based on their class, symbol definitions, and origin (Vectorworks or 3rd party). With each object, you can examine the attached data by its mapping and look at the data fields and sheets, at all the levels of detail (LOD). Here you can also map model object information to IFC standards through custom fields and formulas.

Speaking of IFCs, there is the new ability to reference IFC files so they don’t need to be reimported during the design process if they get changed. Data tags have also been enhanced and expanded.

Sections

Creating section views has been enhanced in this version. Improvements range from being able to control the level of detail for building elements (e.g. windows, doors), to the ability to adjust cut plane settings on individual objects. There’s also the option to show colour fills and planar objects in hidden line viewports.

Doors and windows

2020 has had many small and large improvements to window components – to improve speed and control of placement, LOD detail, as well as to enable rapid modelling and editing. Hipsters everywhere will be glad to know that this release features ‘barn door’ style doors, and there are lots of different types to choose from! And if none meet your requirements, of course they are completely editable. Windows have similar control and LOD updates.

Spotlight

The stage design variant, Vectorworks Spotlight, has enjoyed a variety of updates. These include the ability to generate Heat Maps for lighting designers, rapid seating section generation, DMX patching mapping to keep track of lighting, some really powerful lighting rig schematic generation and a positional Video camera view to plan camera placement.

Conclusion

There are far too many enhancements to mention here and the Landmark, landscaping variant probably needs a review in its own right.

Vectorworks is certainly on a mission to deliver a quality 3D design experience. The interface is fast and it looks great. With new Esri links, improved GIS, history-based editing of geometry and Revit Export in their firs t iterations, it will be fascinating to see how customers use these new features and expand the appeal of the Vectorworks brand.

Q&A

To delve deeper into the new functionality in Vectorworks 2020, as well the development direction the company is taking, we talked to Dr. Biplab Sarkar, CEO of Vectorworks

AEC Magazine: Putting in Revit Export is a major move. Obviously, BIM systems are different under the hood and components don’t necessarily map to other vendors’ components. For this iteration you do just geometry but hint at going further. How will you handle this with export in the future? It strikes me that the only way to get BIM data out of proprietary systems is through a sliced-up sausage approach, in multiple takes from a model residing in different files. Wouldn’t IFC be better than this? You get geometry, plus some intelligence as it drives the creation of Revit components?

Dr. Biplab Sarkar: Our Revit export capability is limited by the ODA [Open Design Alliance] implementation of the export framework in their library. As ODA ramps up their export support for Revit parametric objects, we will also have better exports to Revit. A similar roadmap is being followed in the Revit import process also. IFC import and export is better at this point simply because of the fact that the schema is supported by IFC format, which can be mapped to the data set of various common architectural objects in different products. But there are cases, where a particular object simply cannot be mapped using the IFC schema, and thus is described in IFC as a generic object, in which case the export/import may not create intelligent objects and may be represented differently in other products.

AEC: Vectorworks uses Parasolid at its core. My understanding is that in between the Parasolid engine and the BIM graphics there is a graphics layer which is driven from Parasolid to lighten the load. Why have you taken this approach, and could you explain a little about the implementation of Parasolid in Vectorworks and how it drives the creation of BIM geometry.

Sarkar: Yes, Vectorworks uses Parasolid to represent all architectural objects including walls, roofs, slabs, etc. In these objects, each of the components is represented by solids created using Parasolid. And when you cut a hole in the wall to insert a door or window, the solid undergoes [a] Boolean operation to create the openings. Wall projections and recesses are created similarly using solid Boolean operations. Parasolid is also used in Vectorworks for the creation of solid primitives like extrudes, sweeps, lofts, etc., and for operations like fillet, chamfer, shell, twist, bend, bulge, taper, etc.

When it comes to creating the graphical representation for the Vectorworks objects, Parasolid tessellations are used in general. What we have created in Vectorworks is a layer called VGM or Vectorworks Graphics Module, which simplifies the tessellations geometrically or uses different tessellation details based on how far the object is. It also separates the geometry phase from the actual rendering calls, in addition to creating the scene graph and providing the scene simplification. We use the VGM layer to transmit the scene data from desktop to our mobile app, Vectorworks Nomad, in order to view the Vectorworks scene on mobile devices. Lastly, we have used VGM as the foundation to create Vectorworks Graphics Sync (VGS), which is used for syncing with real-time rendering applications such as Lumion. VGM isolates the operating system specific rendering calls providing an easy way to change rendering contexts like changing from OpenGL to Vulcan or Metal.

AEC: The history tree function and power of Parasolid really pushes Vectorworks into the structural design space. What kinds of links to structural analysis tools are there and is there a plan to develop this as more of a structural solution, maybe a new flavour?

Sarkar: Vectorworks designers want to design the interiors of the buildings, as well as the shells of the buildings. In order to enable our users to model anything they want, we added the history tree functionality which provides the users with freedom and flexibility in terms of editability of the tree.

When it comes to structural analysis, we depend on our sister companies inside the Nemetschek group, including SCIA. We communicate with these products using IFC format as we are strong proponents of the OpenBIM initiative. We do not have plans to develop a pure structural solution. But we have created a structural analysis solution for our entertainment product line. When you hang the lights and speakers from trusses hanging from the ceiling by some chain hoists, how do you ensure the safety of the people down below? For this purpose, we have created a structural analysis solution called Braceworks that helps you to calculate whether the loads and deflections are within the safety limits specified by the local jurisdiction. This helps our users to get their designs certified.

AEC: Looking forward to having Parasolid, a highly accurate and manufacturing-ready kernel at the core, what kinds of links to Digital Fabrication systems are you planning on developing? Would this help get Vectorworks into mass timber, for instance? Is Vectorworks ready to model at 1:1 for fabrication? Big models and detail don’t seem to be conducive to fast BIM modellers!

Sarkar: Yes, Parasolid enables us to create accurate solid representations for most of our objects. It does help in digital fabrication systems. At present, many of our users are limited to 2 ½ D NC machining from our models. We have a number of users in the exhibit design space that use Vectorworks to cut out wooden panels to manufacture the exhibits.

We also have designers using Vectorworks to digitally manufacture high-end cabinets in a very automated and streamlined way. We also see users creating freeform shapes for industrial designs that require 3-axis NC milling. So, in short, Vectorworks does provide models that are suitable for digital manufacturing. We have not seen a lot of our users using Vectorworks for prefab parts for buildings. This is an area that is gaining popularity as the demand for low-cost housing increases.

AEC: While you support native Python and your own Marionette scripting, there are many users of Rhino and Grasshopper. Graphisoft has integrated with it and, now with the launch of Rhino inside, it seems to be able to easily integrate into almost any Windows application, even Revit. What are your thoughts on scripting and could a grasshopper tie in be on the roadmap? There are many brands within the Nemetschek family. Which products will you look to integrate more tightly with next / in the future?

Sarkar: We see Rhino and Grasshopper as conceptual modeling tools that are quite popular in the universities and are used by many of our customers in architectural firms. And, we think these tools are great in doing what they do. What we are doing with Marionette is to help users manipulate Vectorworks BIM objects for design explorations. Marionette also enables the users to create their own parametric Marionette object if the existing objects do not suffice. But we do see a lot of upside to having Grasshopper integrated with Vectorworks, especially to drive pure geometric designs.

We want to integrate with several products in the Nemetschek family. As you know, we utilise the Maxon rendering engine in Vectorworks and integrated PDF-based workflows of Vectorworks with Bluebeam. We also established interoperability using IFC with SCIA (Structural Analysis), DDS-CAD (MEP) and Solibri. In the future, we want to create tighter integration with companies like RISA or dRofus.

If you enjoyed this article, subscribe to our email newsletter or print / PDF magazine for FREE