Sensori is a compelling offering for rapid site capture that relies on low-cost devices, speedy capture technology, automation and the power of the cloud. AEC Magazine spoke with the team at this New Zealand-based start-up

Technology has a habit of transforming complex jobs requiring high skills levels and making them easier and faster. For example, today’s surveyors frequently use small, light, handheld laser scanners that enable them to walk around a site, capturing as they go. That’s thanks to the wide adoption of simultaneous localisation and mapping (SLAM) and SLAM-like technologies, and it’s a far cry from the tripod-based, stationary scanners of the past.

Likewise, with photogrammetry, instead of painstakingly stitching together hundreds of thousands of photographs, handheld video can now provide enough data for photogrammetry engines to generate pretty accurate point cloud data.

Based in Wellington, New Zealand, Sensori Systems is a new start-up aiming to bring persistent cloud photogrammetry to the AEC market. Founded by Brett Skinner and Roderick O’Hara, the company has already worked on some great projects: O’Hara has devised holograms and maps intended for explorations of Mars, and they both worked at digital visual effects and animation company Weta Digital, best known for its work on the Lord of the Rings films.

Sensori aims to deliver rapid, accurate 3D capture of spaces and sites using photogrammetry. All you need is a handheld device with a fisheye lens (providing an ultra-wide=angle view between 180 and 360 degrees), and a few target markers to aid auto-registration. You then walk around the area you want to capture, taking a video.

The company recommends using a camera with a big sensor, especially when working in darker environments. To capture a 700 square metre area might take around 10 mins. The data is then uploaded to the cloud and the Sensori system creates a 3D model. This can be streamed off the server for viewing and manipulation in real time. Using streaming technology, results might start off on the coarse side, but as more data comes to the browser, fidelity improves.

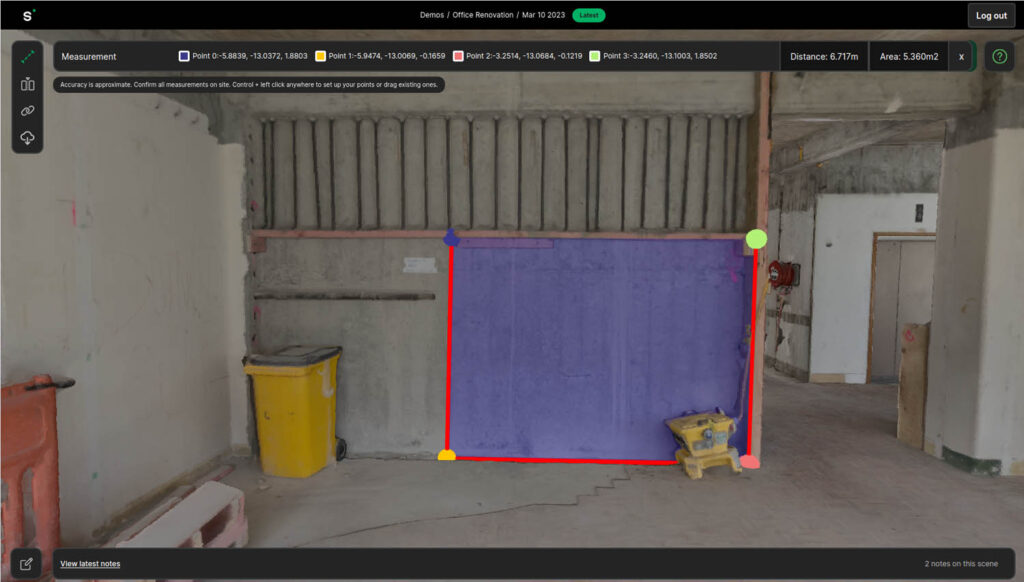

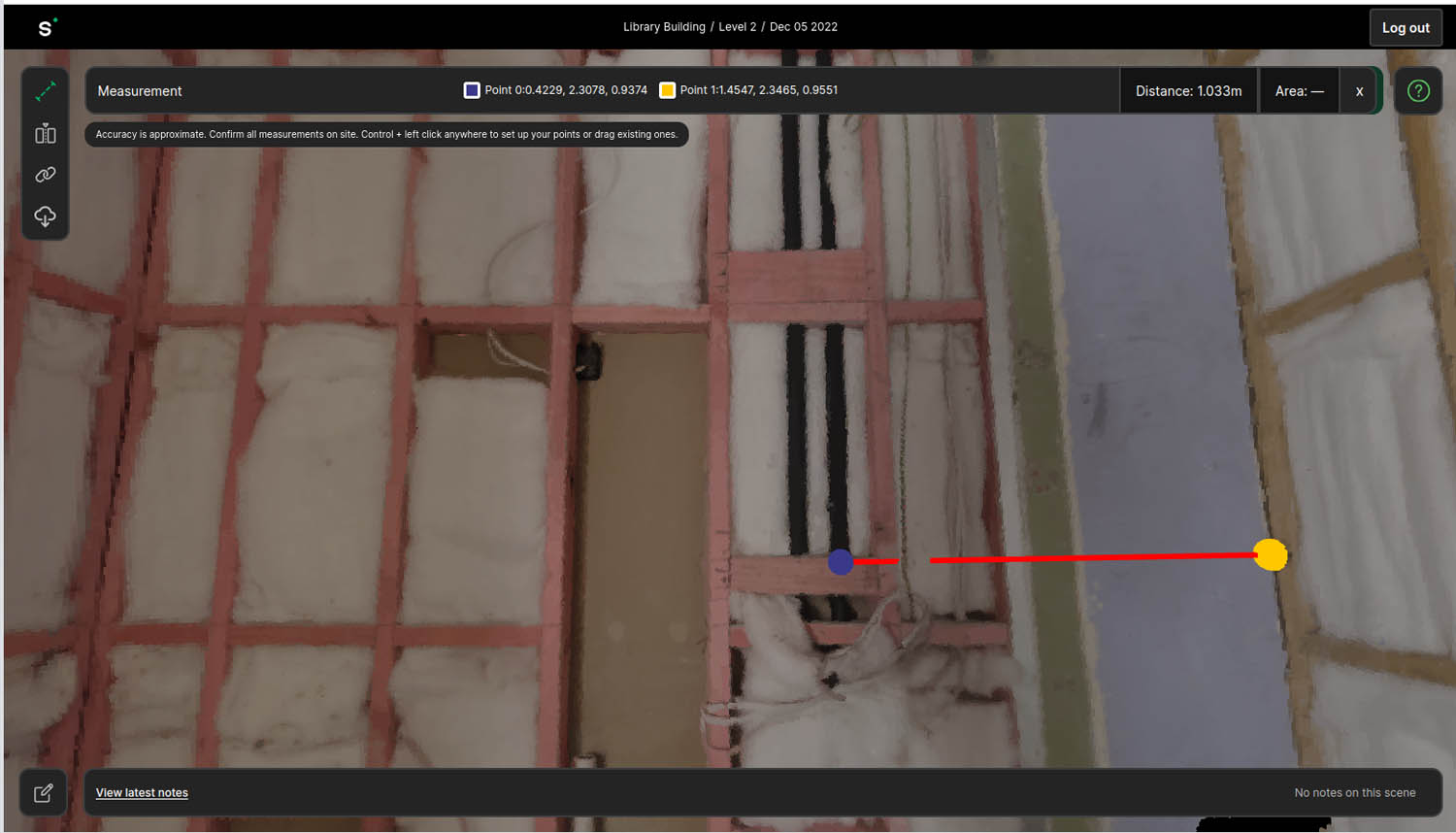

Once you’re happy with the model fidelity achieved, you can take measurements, add notes and get access to the embedded video frames, so the system offers a hybrid of both 3D and 2D results. Environments can be copy and pasted by links into an email or spreadsheet, bringing other users into the model at the same point, with the same view.

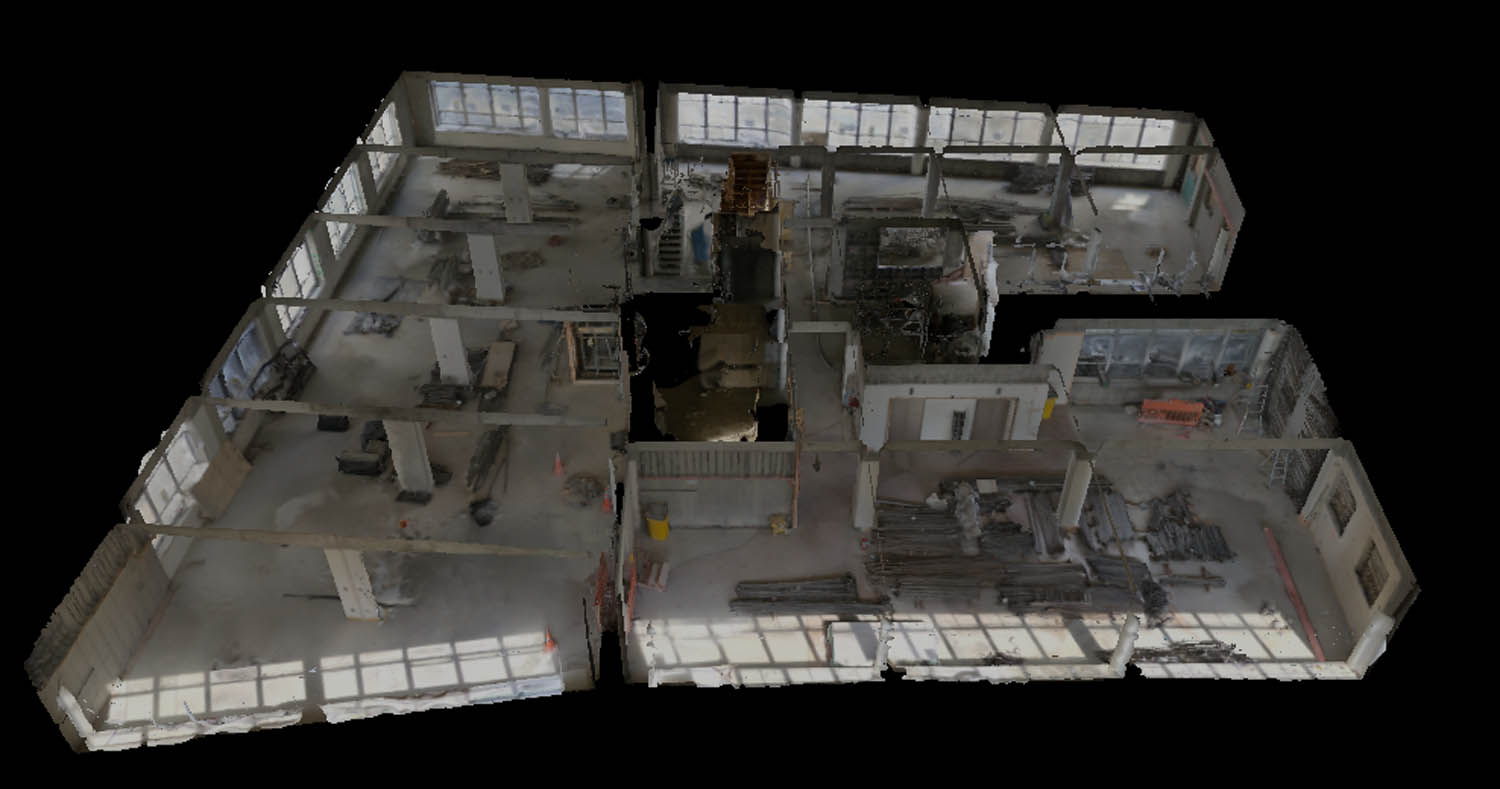

According to the Sensori team, what most contractor customers do is send unskilled workers to a site to capture video walkarounds, and then quickly download a point cloud or glTF textured mesh back at base. These can then be loaded into Revit or Rhino.

Sensori by numbers

Sensori has so far built a niche for itself in renovation work, where firms want to see post-internal demolitions to bring out the geometry. These are not survey-level results, but they’re good enough and come at a sufficiently low cost, and may perhaps prove useful for off-site fabrication of components like steel framing.

Sensori claims that the accuracy of its models is 0.1 to 0.2% accuracy down to 10mm, which, potentially, is like best-in-class mobile laser accuracy. Static total stations remain the gold standard but come with significant time and cost implications. Sensori, by contrast, is a full software-as-a-service (SaaS) offering and can handle workflows that combine survey data with its photogrammetry data for higher accuracy.

The start-up has based its cost structure on an upfront processing fee, as the team wanted to avoid charging customers for accessing their own data. After all, that might inhibit the use of cloud-based models significantly. Instead, Sensori charges by the number of images or frames of video uploaded. The costs associated with a 700 square metre office, for example, would be around £120 to £150 – and this fee includes five years of hosting.

Sensori is a compelling offering for rapid site capture that relies on low-cost devices, fast capture technology, automation and the power of the cloud. The company has had its service used to capture sites up to around 10,000 square metres and its connectivity to core BIM and design solutions just adds to its potential value.