An optimised cloud-based digital construction workflow is helping the ECC Group keep its largest projects on track, improve site productivity, cut contractors’ unseen costs and reduce the impact of Covid-19.

Recognised as one of Ireland’s foremost engineering companies, the award winning ECC Group operates out of the UK and Ireland. Current live projects include the construction of numerous data centres for one of the world’s largest social media platforms, often up to 400m in length, along with other vast structures for pharmaceutical and life science companies.

With 2020 throwing up innumerable challenges, ECC Group CEO, John McGoey, was intent on delivering an enhanced service for his clients that would keep their large infrastructure projects on track. Required to provide structural and layout information to the contractors on these projects, McGoey was using 3D laser scanning as the best option for the fast collection of accurate point cloud information that would record every detail.

The existing workflow would then see this scan data sent to the office based ECC BIM team where it would be processed in Trimble RealWorks software and then stored, ready to be retrieved when progress meetings etc. were scheduled.

However, with the potential delays that Covid-19 could cause and the need for remote working, McGoey felt that a fresh look at how he collected, processed and shared each project’s survey data would bring enduring benefits to both existing and future contracts.

Straight to the point

As a curious and committed supporter of technology and a long-term user of Trimble instruments, McGoey contacted Trimble’s UK and Irish distributor, Korec, to talk through some possible approaches on how to get better use out of the data he was collecting.

In particular, how he could ensure that all the project’s stakeholders – including the QC team, senior management and package management – could have access to this rich and up to date information whilst avoiding site visits and overcoming the issue of files being too big to email.

By better sharing the latest site data, McGoey felt that it would vastly reduce the risk of delays and rework and also keep people fully informed, all from the safety of the office rather than on site which could result in all parties crowding around a paper plan or single screen.

The living document

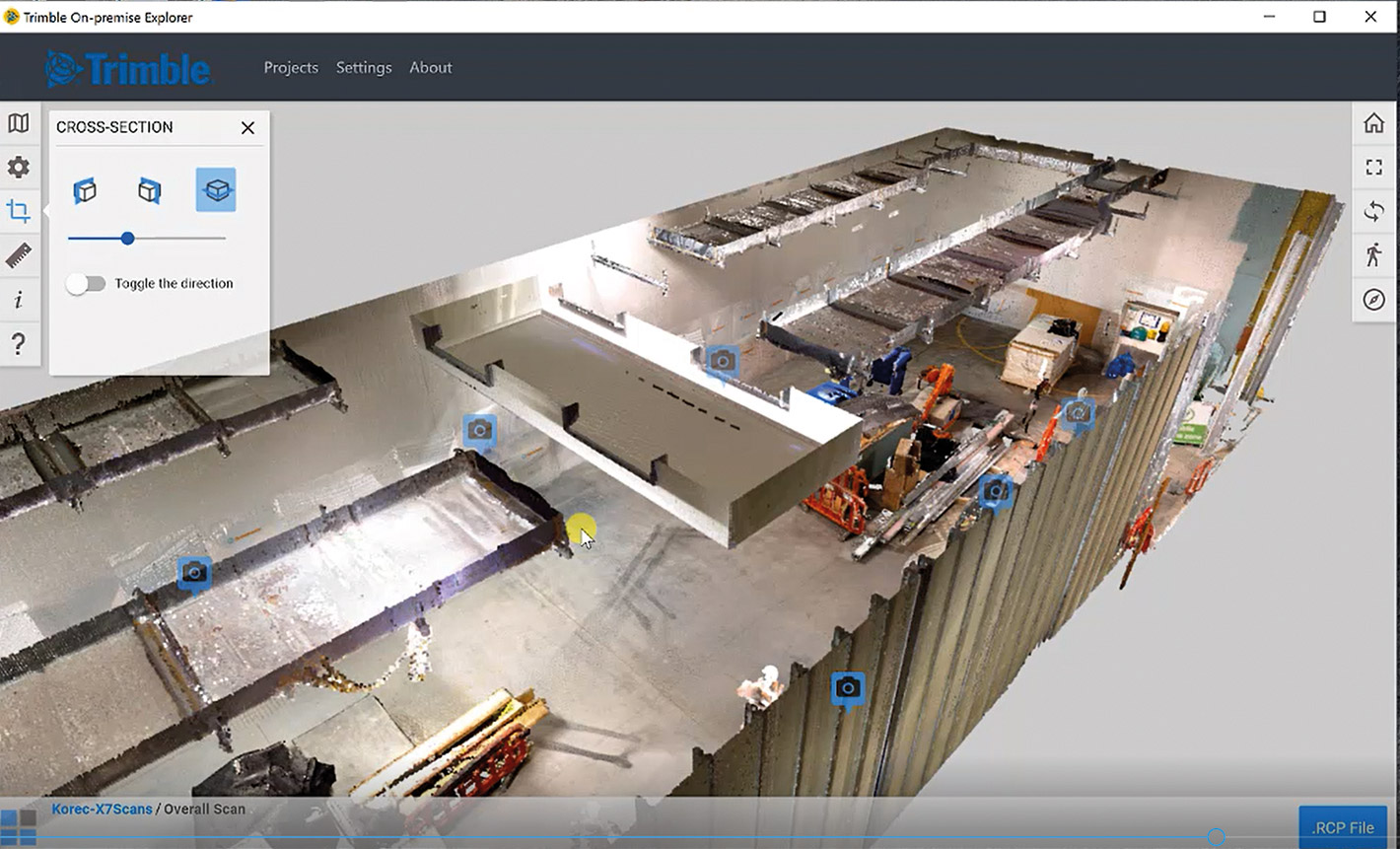

Following a consultation with Korec and Trimble, McGoey turned to Trimble’s Cloud Engine software (TCE). The software creates a ‘living’ document of the scanned point cloud data, ideal for monitoring the construction process and detecting clashes etc. in a format that could be easily understood by technical and non-technical stakeholders.

TCE allows each scan dataset to be shared as a simple URL link (identical to inserting a web link in an email) added as a note to a 2D drawing which is then shared with the client and contractors by email.

From the client perspective, this allows them to view the 2D plans and additionally, via one simple click, to be transported into an interactive 3D model of the build, complete with imagery. Here, they can zoom, pan, check coordinates, tag elements, add notes and PDFs and of course view the scan, all whilst discussing the project plan with the ECC team.

Clear communication

Following the implementation of the new workflow, McGoey reports that the benefits have been diverse. For a start, as opposed to basic 2D plans, the software is making full use of the rich 3-dimensional point cloud data and shares it in a format that is both intuitive and quick to learn. This has greatly increased client engagement and the overall understanding of a project’s progression.

The early morning scan team arrives on site and the data is processed, with the URL link emailed to stakeholders by the close of play that day, ensuring that all relevant parties have access to the most up to date data

As well as fostering trust between the parties, this increased engagement reduces misinterpretation and misunderstanding, as it allows the most realistic view possible of the project.

From a safety and site management perspective, this workflow reduces on-site personnel to the bare minimum with just one operative required to collect the 3D data and the accompanying imagery. Less bodies on site means less accidents, less person-to-person contact (vital at this time), and frees up staff for other, safer, more valuable office-based tasks.

The TCE software is also free to use for all nominated stakeholders and the simple, intuitive layout ensures that very little (if any) training is required from the client side. This means that contractors can considerably reduce unseen costs such as travel. QA teams can be managing multiple global projects and therefore having access to this quality of data from wherever they may be significantly reduces unseen costs through remote inspections, QA and sign offs etc.

Same day turnaround

With a highly effective workflow tried and tested, McGoey further enhanced his scanning operations to increase efficiency. Already using Trimble’s highest spec laser scanner, the TX8, which was perfect for long range scans, he supplemented it with the addition of a Trimble X7.

With a schedule of up to 50 scans per day he ensured that the programme was planned at least a week in advance detailing scan density etc. Additionally, in order to speed up operations, the tripods were often placed on wheels for easy manoeuvring around the vast floor areas.

However, it is the functionality of the Trimble X7 that has had the most impact. The X7 automatically registers scans on site and the size of the data files are smaller and more manageable reducing processing time in the office. So much so that McGoey can now offer clients a ‘one day’ service.

The early morning scan team arrives on site and the data is processed, with the URL link emailed to stakeholders by the close of play that day, ensuring that all relevant parties have access to the most up to date data.

McGoey is already looking at the next step in this new workflow recently supplying two sub-contractors with Trimble’s XR10 HoloLens System, a mixed reality headset purpose-built to fit into an industry-standard hardhat. This technology allows ECC or the sub-contractors to bring models of their client’s construction projects out of the screen and onto the site so that they appear lifelike and can be moved and changed depending on how the user interacts with them.

Models are given context when overlaid onto the real world hugely assisting the on-site team. They can also be used for remote sessions and progress reporting – ideal for keeping people apart during Covid-19.