Will Norton, structural engineer at McElroy consulting engineers and project managers, explains how Structural BIM has revolutionised the way McElroy undertakes design projects.

Like many small to medium enterprises (SMEs), McElroy recognised that Building Information Modelling (BIM) could offer a host of benefits but had yet to investigate it fully due to resource constraints. Acknowledging that BIM was fast becoming the norm and with a desire to capitalise on its proven benefits, structural engineer Will Norton spearheaded McElroy’s first ever BIM project using Fastrak, CSC’s steel building design software, and Autodesk Revit.

By employing what is often known as ‘Structural BIM’ or ‘Internal BIM’, McElroy started by sharing project data within its own structural design office, communicating data between the engineer’s code-compliant design model in Fastrak, with the technician’s Autodesk Revit model. McElroy’s primary objective was to understand and benefit internally from Structural BIM before later adopting ‘External BIM’, which would enable external data communication upstream and downstream with the client, architect and contractor.

McElroy’s first project

McElroy’s first Structural BIM project was an extension to an existing building with relatively simple geometry. It was specifically chosen so the team could fully learn the workflows that are essential for effective BIM synchronisation; to build confidence before implementing BIM workflows on larger and more complex projects, and for External BIM at a later date.

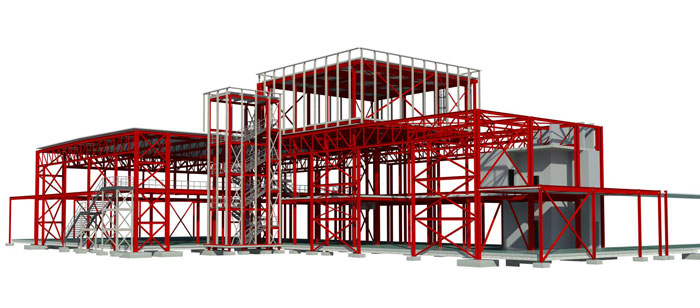

The project required a 1,300m2 extension to be added to an operational building owned by Teva Pharmaceuticals Group, consisting of a 17m high steel braced frame weighing 175 tonnes. Using Integrator, a free plug-in from CSC that enables either full or part models to be synchronised between Fastrak and Autodesk Revit, McElroy started by importing the general arrangement model from Autodesk Revit to Fastrak.

As the design progressed, there were inevitable changes to both the set out and design philosophy and McElroy had to assess the viability of various design options and locations, for example masonry walls compared with concrete lift cores. The materials and locations were amended in Autodesk Revit and then synchronised with Fastrak, whereby McElroy’s structural engineer could investigate the effects on the structure. The changes in Fastrak were then synchronised back to Autodesk Revit; a true round-tripping which was performed numerous times on this project.

“Integrator gave complete control when synchronising models,” Mr Norton said. “We could choose whether to include or exclude different member groups and geometry settings and it provided logical colour-coding so we could visualise the design changes. It was abundantly clear as to which members were new, modified or deleted.

“The position of various elements, such as lift cores and mezzanines, within a proposed building envelope can frequently change at scheme design stage and the Teva extension was no exception,” explained Mr Norton. “Without Structural BIM integration we would have had to re-model the structure twice for each design change, once in Fastrak and again in Autodesk Revit. With seamless synchronisation between the two software packages we were able maintain a single model, sharing all the latest data. The implementation of Structural BIM has streamlined our design approach, reduced the risk of errors, provided huge time saving and improved communication enormously.”

The future of BIM for McElroy

Having been rewarded with such success early during the Teva project, McElroy is now utilising Structural BIM on two larger steel frame projects alongside the Teva Project. The first is a 210 tonne upgrade to an existing facility and the second is a larger scale newbuild pharmaceutical facility weighing in at 1,750 tonnes. Structural BIM has now been adopted for all medium and large sized projects at McElroy.

“Clients are increasingly expecting 3D visualisations at the consultation stages of projects,” Mr Norton commented. “We now produce 3D models that help to communicate our designs effectively, an integral aspect of what Structural BIM can offer.”

Due to the time saved modelling, McElroy has seen projects become more profitable and engineers have been able to cost design schemes more accurately due to the more efficient working methods afforded by Structural BIM workflows.

“The future is BIM, whether it be Structural BIM or External BIM,” Mr Norton said. It has made McElroy more competitive, increased productivity and enabled us to deliver a better service. Those who adopt BIM place themselves at a distinct advantage in the market.

If you enjoyed this article, subscribe to AEC Magazine for FREE