Autodesk University in Las Vegas is the company’s key opportunity to share its latest updates and present its vision for the future. Martyn Day reports on some exciting new technologies, including one that could eventually replace Revit

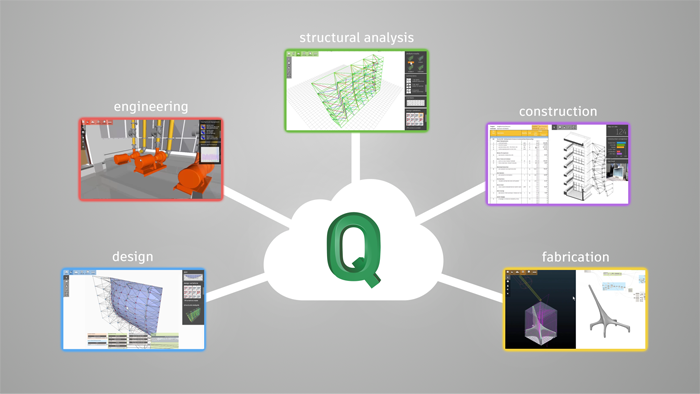

When you have a fundamental new AEC design technology up your sleeve and a huge captive audience, one can imagine that it’s hard not to get a little bit over-excited. So it was little surprise that Amar Hanspal, senior vice president, products at Autodesk, chose Autodesk University to unveil Project Quantum, a new cloudbased BIM technology that could eventually replace Revit.

Project Quantum is literally the next generation BIM platform for Autodesk, that we first wrote about back in November 2015. It takes the view that collaboration is a key component of AEC design and so centralises its database in the cloud, here on Autodesk BIM360.

Autodesk thinks that, depending on the discipline you specialise in, you will get different capabilities relating to your job function — architects get walls, doors, windows; structural engineers get structural members etc. All is fed from a single version of the truth and managed on a central server.

One of the weaknesses of Revit is the structure of its database, developed before the days of the cloud and streaming and leading to huge datasets being sent around the planet. I am guessing that the ‘Quantum’ in the project name is some reference to the ‘granularisation; of the BIM data.

Hanspal explained that Autodesk was committed to keeping compatibility with Revit and Revit models as we know them today (which I would guess is quite a tall order) and the system is being designed with the concept that users will be ‘always on’, meaning constantly connected to the central database. There will be some exceptions for when users want to work offline but submitting and resynchronising comes with some problems that need to be resolved.

Autodesk was showing Project Quantum to customers at AU. The murmurs we heard was that it couldn’t really do much yet and there were some grumbles about being forced into using the cloud with BIM360. We will have to wait and see what comes out as development progresses. However, we are sure it will be able to handle larger models and play better with other applications such as Autodesk Fusion.

While Revit is indeed old code and advanced users get frustrated with its performance and capabilities, especially in teamwork, I suspect that it will have a long shelf life even after Quantum goes live as the huge task of replicating a BIM tool, with all the complexity will take years to complete. So if you are either a long term Revit customer or have just bought into Revit as a BIM tool, there’s nothing to panic about quite yet. We will have a whole lot more on Project Quantum in the next issue of AEC magazine, so stay tuned.

Jeff Kowalski

At Autodesk University, Autodesk’s enigmatic Chief Technology Officer (CTO) traditionally gives the first keynote talk and always gives a thoughtful take on where design technology is going. Kowalski gave a great talk covering design tools from the ancients to the future. In fact, many of the prospective technologies he has talked about in the past five years are now becoming reality, especially the use of robots and machine learning. These powerful tools are now combining to give designers ‘infinite expressability’ which will help shape the future by amplifying their ideas.

Machines have gone from being taught how to play games by programming, to teaching themselves. Machines now learn in ‘machine time’ so they can learn something by running thousands, millions of scenarios simultaneously and learning from the output. Kowalski went so far as to say that machines are now starting to be creative and be able to create new works of art and new designs.

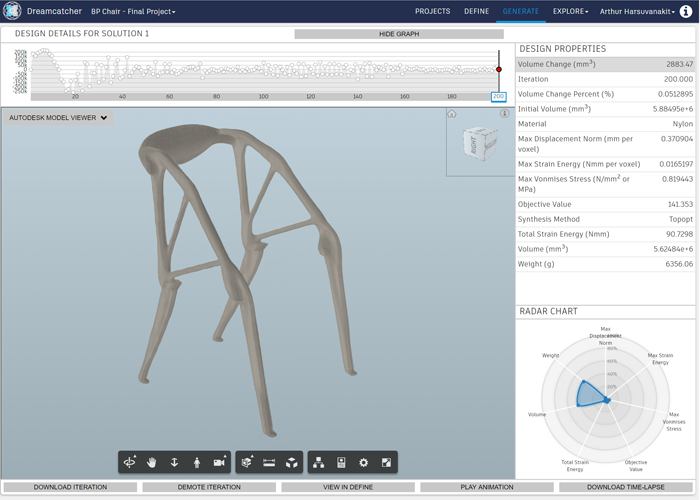

Autodesk Dreamcatcher technology, which has been shared with only a handful of customers, has been consuming millions of 3D models and learning from typically designed and manufactured parts. Dreamcatcher has been used in aerospace prototypes already and this year we were given the redesign of a car suspension component. Dreamcatcher gave a new optimised geometry solution and a version with internal lattice structure, learnt from how bones have internal structures. Autodesk is using the technology on its new Toronto office building. Taking survey data from employees and constraints of the layout, Dreamcatcher optimised the layout for least distraction, best views and connectivity of teams, reconciling competing goals.

The big news is that Dreamcatcher becomes available for all to use next year. This could be a serious game changer in the way we design, where Computer Aided Design actually does aid the design process.

Machine learning and AI

Kowalski’s Keynote was not just words, there were many examples of the application of computer aided thought available at the event. With the increasing digitisation of manufacturing, the use of robots, drones and 3D printing, all these combine to provide some incredible possibilities for all designers and manufacturers. While this seemed like science fiction five years ago, it’s now becoming science fact

Dreamcatcher

As mentioned earlier Dreamcatcher will be available as a service to customers next year. One of the fantastic demonstrations was a hot rod car frame, created by Hack Rod. Felix Holst of the company was on hand to explain how this chassis had been designed using Dreamcatcher to optimise the weight and strength of the car body, based on telemetry data of a previous generation car, which was fed into Dreamcatcher. The result was an incredibly lightweight vehicle with unusual lattice work. Felix told us that he also used Virtual Reality (VR) to explore how the transmission and gearbox would fit into the actual chassis before any fabrication had taken place.

By using VR, the actual installation went without a hitch. Looking ahead Felix thinks that, based on chassis designs, customers might be able to design their own car body and have the software optimise the design to work on the available running gear.

The software will always make sure it’s a viable design and all the mount points would fit. Digital design and fabrication are going to make a big impact on what is possible in the not too distant future.

Machine learning in AEC

This application of machine knowledge was also prevalent in many of the Autodesk AEC presentations. This wasn’t just from Autodesk but also from partners and other independent developers which were looking to apply machine learning to prediction, analysis and monitoring in construction and maintenance. Here are some of the highlights.

Project IQ: Autodesk has a new project in development called Project IQ. The aim of the service is to provide intelligent assistance by mining construction project data and delivering predictive analytics. As an ‘always on’ system, Project IQ continuously learns from project outcomes.

One example showed a construction firm with multiple projects, given weather conditions, progress, rework, activity and inspection status. The heads-up display showed which projects had the highest risk for that day and indicated which criteria was causing the risk warning. By bringing this predictive capability to construction, problems can be addressed before they happen, reducing risk and costly rework.

Pillar Technologies: Continuing in the vein of risk management on site, Pillar Technologies (pillar.tech) gave a description of its site monitoring hardware. These tough, weatherproof rectangular A4 boxes contain a plethora of sensors which can be distributed about a site. The box’s sensors feed back live data on weather conditions, moisture, smoke, temperature and fire and send alerts when conditions become dangerous. They also offer predictive analytics, so contractors can stay on top of their time and budget allocation.

The technology also benefits insurance companies and property owners, who have a stake in a site’s safety. One of the advantages given was the case of a concrete pour that was done prior to a water leak happening. The system sent out an alert and the construction management team could remotely identify the reasons why there was a problem with the floor.

Smartvid.io: One of the most interesting new applications of machine learning we saw came from a developer called smartvid.io. The team had previously sold their last company, Vela, to Autodesk which became BIM360 field. Their new venture takes construction images and video and applies artificial intelligence to identify construction elements in photographs. So the computer can automatically add meta data to photos that have objects it has learnt to identify, such as scaffolding and structural beams.

Taking this idea further, the team demonstrated how a video could be made when driving through a tunnel. On each frame, the AI can identify cracks in concrete and, having been trained by a human expert in rating good to bad cracks, can then automatically identify cracks that need immediate attention and log the others for reference for future scans. All this was performed from video taken by a GoPro camera on a car roof or from still photos from a tablet or phone.

These kinds of technologies can help us process huge amounts of collated data, and real time information giving construction managers and safety specialists incredible insight into the state of building sites and pre-built infrastructure. Our ability to monitor and become omnipresent is available now.

Software development

Amar Hanspal’s remit has grown each year, to now pretty much being in charge of all software development of commercial products at the company, from AutoCAD to the new cloud-backbone for next generation products. Hanspal hosted a single session that concentrated specifically on Autodesk’s product development. It lasted an hour and a half, so we do not have room to go through it all, only the highlights.

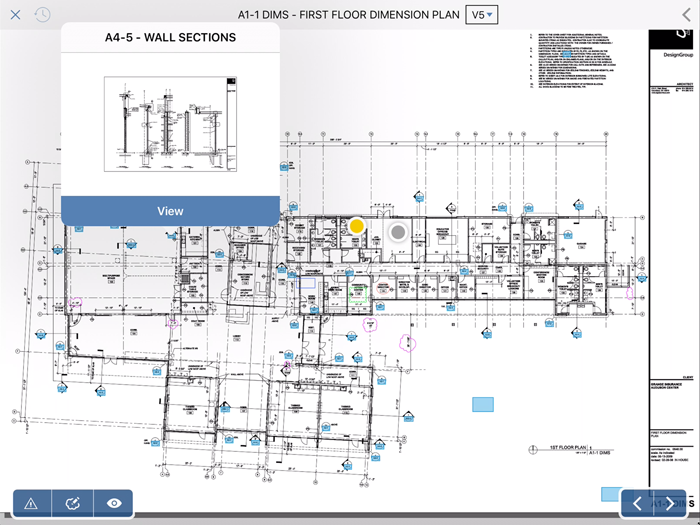

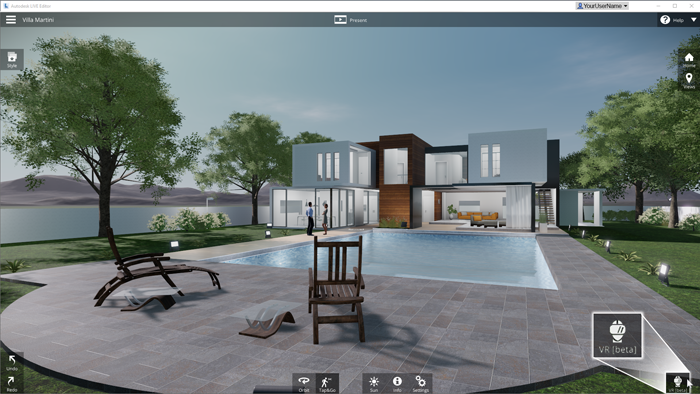

The key new take aways were Autodesk Live, which takes Revit models and creates interactive experiences on screen and in VR (Occulus / HTC Vive) within two clicks. BIM360 docs has seen a lot of work since its introduction last year and it’s now looking pretty good. There have been over 50 updates since it was launched including hyperlinks to 2D drawings, OCR title blocks, raster PDFs, search, improved mark-up, linewidths, add photos etc.

Hanspal recognised that Autodesk produces too many updates, too often for some customers, and promised to work at easier ways to deploy updates without causing sleepless nights for CAD managers. Updates will eventually update as easily as they do on a smartphone.

Hanspal ended by saying, “Autodesk is moving to provide integrated platforms and experiences, connected capable on demand experiences with no compromises.” #

Autodesk Forge

Autodesk has spent many years rewriting core parts of its code for the cloud. These components (or services) are hosted in the cloud and are accessible not just to Autodesk developers but also to the host of third-party developers who make up a massive community.

Through this Forge initiative, Autodesk is now engaging with these developers to entice them to develop cloud-based applications to run with their next generation products or make entirely new products which rely on Autodesk online services.

It now seems to be gaining traction and, from the developers we have talked to, is genuinely seen as an exciting opportunity. Previously, developers would create an add on, or license an OEM version of a single Autodesk application which was expensive to resell. Now with a services backbone, new financial models and distribution methods, it appears game changing. Expect to see more applications from third-party developers.

Exhibition floor

Walking the exhibition floor is now one of the most enjoyable parts of AU as there is plenty to see and do — hands on technologies, innovative products from customers, new hardware, new software, wearables, drones, robots, CNC machines and many Autodesk developers with add-ons for Autodesk products.

Historically, back in the days of AutoCAD, these would be simple things like symbol libraries and plotting tools but nowadays, there are many featurerich products that can radically benefit the design process like Arup’s crowd simulator, MassMotion or drag and drop VR for Revit with IrisVR.

Autodesk brought two of its large robot arms to perform live 3D printing on a large scale. Think Westworld! Fenced off from the public, you could watch the Robot go through its paces laying down layers of black plastic, building all sorts of 3D components. Just over on the next aisle were some large metal 3D prints, showing how Dreamcatcher optimisation reduced the weight of the suspension arm dramatically and a huge metal fin structure which was 3D printed for a roof design. Hack Rod’s chassis took centre stage, as it should, and there were many wooden chairs again designed using the Dreamcatcher optimisation algorithm.

Autodesk VR: Virtual Reality is a hot topic at the moment and Autodesk is currently researching its potential uses. While many may consider the VR experience to be an end in itself, Autodesk is looking at how we can design while in a VR environment, not just to explore the model but to model and shape intuitively.

There was a dedicated space for some hands-on VR booths running Autodesk’s experimental VR tools which were working with HTC Vive headsets. Using the VR kit it was possible to interact with, edit and draw on a 3D model of a car, while looking at meta data and design feedback. While embryonic, it gave a clear indication that Autodesk feels that VR applications can play a role, not just in the sharing the experience of a design, but also to do design work in a virtual space.

Workstation fun: It’s not just software that’s advancing but also hardware. HP took the opportunity to launch a new, tiny, quiet and powerful workstation called the HP Z2 Mini, which starts around $699. Sean Young, worldwide segment manager, product development & AEC presented us with a typical tower workstation explaining all the benefits of the new machine, only to pull the chassis off the table to reveal the exquisite, miniature workstation. On opening it up, the design was excellent and the fan virtually noiseless.

On Microsoft’s stand it was the first time we saw the Surface Studio desktop giant (28”) touchscreen workstation. This highly flexible large format screen is just fantastic to use. The screen is on hinges, that make it manoeuvrable and perfect for a drafting orientation with pen / stylus. It seems with Microsoft finally getting the Tablet market right, it’s not just content to rest on the Surface Pro. This is a machine made for designers that want to sketch and not be limited to the small form factors and feature-limited applications that mobile devices have been hampered by.

Leica BLK360: A major surprise came in the small but perfectly formed shape of a joint venture from Leica and Autodesk, combining Recap on an iPad with what has to be one of the most gorgeously designed, highly portable laser scanners we have ever seen.

Leica Geosystems’ new BLK360 is a self-levelling, miniaturised 3D imaging laser scanner which weighs about 2lbs and easily fits into a bag. It captures fullcolour panoramic images overlaid on a high accuracy point cloud, accurate at distances up to 60 metres. The device captures HDR images, as well as thermal images, and has built in lights so it can work in low light. Operation is extremely easy with a one-button press. The device was described as waterproof and could be mounted on a tripod, on a ceiling or on its ingenious built-in stand. In fact the design of the device and its dome carrying case is nothing short of exquisite.

From the outset the new scanner was designed to work with Autodesk’s ReCap 360 Pro and the new ReCap 360 Pro app for iPad. As there’s no display on the scanner, control is provided within Recap on the iPad Pro. There is no user accessible storage on the scanner; all data is sent to the iPad over WiFi. Typically a full 360 degree capture will take three minutes. The app filters and registers scan data in real-time. After capture, ReCap 360 Pro enables point cloud data transfer to a number of CAD, BIM, VR and AR applications.

AEC Magazine’s view is that this is an industry game changer. The price and ease of use make this ideal for architectural firms and in the cons truction space for monitoring building progress. It’s also possible to use multiple devices and control them from Recap on the iPad Pro. This has obvious benefits in scan to BIM applications especially for old nonlinear buildings.

BLK360 & Autodesk ReCap 360 Pro Bundle will be available to order in March 2017. The anticipated bundle suggested retail price is $15,990/€15,000, which includes: BLK360 Scanner, Case, Battery, Charger and an annual subscription to ReCap 360 Pro.

DAQRI Smart helmet: While Augmented Reality is currently overshadowed by the explosion of Virtual Reality headsets, plus the Microsoft Hololens gets all the focus, DAQRI has produced one of the most usable and incredible head displays we have seen, all built into a hard hat which protects the user onsite. This is directly aimed at the construction and remote inspection market.

Operating wirelessly, the helmet includes Thermal vision, so dynamic views can include temperature feedback, which can also be recorded. Guided work instructions can be fed to the helmet for step by step processes. It’s even possible to ‘tele-presence and see other colleagues’ live point of view and assist them by augmenting their field of view with indicators and draw around objects. This is an amazing product that looks destined to have a huge impact in our industry for site work.

Closing thoughts

Another Autodesk University completed and there was plenty to see and do, lots of new technology with massive future implications especially for AEC industries.

It was interesting that Autodesk unveiled Project Quantum at such an early stage. However, Revit is relatively unthreatened in key geographies and there are many expert customers frustrated with the current generation of BIM tools and wondering what is next, especially when they are paying subscription. Showing Quantum will not stop Revit sales and Autodesk needs to migrate its AEC software more to the cloud. A port of Revit, as it stands, makes no sense when not just the tool but the very process of team design needs to be rethought. Keep an eye out for our exclusive deeper dig into Project Quantum in the coming weeks.

In terms of current products, BIM360 Docs had the big push and the general interconnectedness of Autodesk’s solution appears to be really coming together.

While many customers see themselves as ‘a Revit user’ or an ‘AutoCAD user’, the ecosystem of products is becoming more seamless and delivers on the company’s teamwork vision. The main issue is that it has to be all on Autodesk’s terms and hosted on its servers, where using the suite of Autodesk applications is easier, even if they may not all be best in class.

Before and during the event from talking with several Enterprise License customers there seems to have been considerable unrest at the pricing structure for this cycle. Revit is now the essential BIM tool, and customers demand projects are completed in it, so some customers feel hostage to the proprietary format. So, the concept of duplicating that in infrastructure terms as well may be less than appealing.

Virtual Reality is here and for average size firms, very affordable. With Autodesk making this available in two clicks, every firm with Revit can get the benefit for customers and design teams. We highly recommend getting into this technology now as it’s a clear differentiator for firms which have made the step to 3D.

It was impossible to escape the world of Robots and AI. Autodesk is truly unique in its approach to developing this kind of technology and if it can be made easy enough to use, it will literally turn design on its head. Conceptual design, combined with powerful analysis, machine-derived solutions and digital fabrication will create new vocabularies for shapes and forms. We just have to look back at the cars of the 1970s and compare them to what is produced today to see the influences of CAD and 3D modelling on design. We don’t fear that computers will take over the process of design but will ensure and proof concepts, while the designer opts for aesthetics or weights the generated design solutions.

AutoCAD was mentioned in passing serval times during the week, to cheers from the crowd. For many attendees it’s what they would have gone back to use in their design offices and sometimes a 2D drawing is quick and all that needs to be done to convey information. However, seeing what’s possible now, especially in products like Autodesk Fusion and seeing the output in the physical form of the Hack Rod and other curated products on show, it’s clear that the revolution in design and manufacture is now well and truly underway.

The keynotes: Autodesk CEO, Carl Bass

Autodesk CEO Carl Bass kicked off his talk with his own observation that, in the past, some of the keynotes sounded like science fiction, as opposed to reality, but pointed out what seemed like the impossible two years ago quickly becomes the possible. He cited Space X’s re-usable rocket, self driving lorries and Zaha Hadid’s design for a building that’s totally manufactured off site and assembled.

Bass pointed out he has met more auto execs in the last year than he has in the previous five because there is a degree of anxiousness as automotives recognise that everything is changing – autonomous cars, car sharing and electrical powertrains. Drivers are becoming passengers; the next generation may never own a car because transportation is becoming a service.

Many firms have been in denial about electric cars and now are playing catch up. As all these happen together the industry faces disruption. Autodesk also faces disruption and Dreamcatcher is one of the responses to this, designing more efficiently, machining more efficiently. Teamwork will also be a key element in this and he showed a great video comparing 1950’s F1 pitstop vs today’s (tinyurl. com/pit-stop-AU) then asked delegates to keep an eye out out for disruptions in their markets and embrace them.

Christian Benimana, of the African Design Centre in Rwanda give an inspirational talk on how he wanted to be an architect but his country didn’t have an architectural college, so he applied for scholarships abroad. He was accepted in Shanghai which was great but he had to learn Chinese in 12 months!

Benimana graduated and went back to Rwanda where Africa faces some extraordinary challenges. By 2050 the population is expected to rocket to the population of 2.5 billion (that of China and India combined), with 1.4 billion living in cities. This represents 700 million more homes than there are currently in Africa. At present, there are 125,000 architects in Italy; Africa has just 35,000.

Benimana’s talk is well worth watching. Anna Nixon, 16 years old, talked about how the First Robotics competitions have engaged her and allowed her to apply her skills by building robots to compete against one another. Her basketball-throwing robot, called Prometheus, threw balls into the crowd and while that was cool, a 16 year old girl with the level of confidence to address a 10,000 crowd was probably still the most impressive thing. She ended up asking for easier to use tools that don’t need years of learning.

Autodesk University – coming to London

For those unfamiliar with the University set-up, AU is four days of hands-on lessons, exhibition, mainstage talks from Autodesk management and customers, some show and tell sessions and plenty of socialising with the ten thousand or so faithful that make the yearly pilgrimage.

The good news is that Autodesk is now expanding AU to appear in different geographies and Autodesk will be holding a two day London-based event in June 21-22, 2017 at the Tobacco Dock, E1.

It will be interesting to see how it compares to the Las Vegas original, I suspect they will have to pipe in the never ending jingling of the millions of slot machines into the public spaces to establish the same ambience. Other AU events already take place in Australia, Russia, Brazil and China. Expect to see events in Japan, Germany, Mexico, Istanbul, India and South Africa.

If you enjoyed this article, subscribe to AEC Magazine for FREE